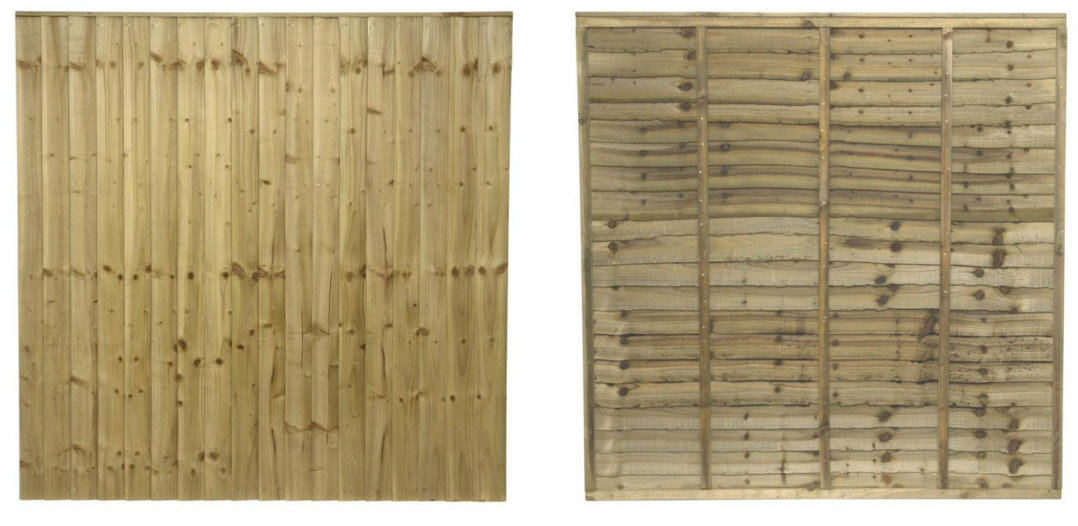

Featheredge vs. Waney Edge Panel

Understanding the difference between various panel styles helps in the decision process when choosing and installing a new fence using panels. Two popular choices are both Waney and Featheredge panels.

Read on for more information regarding both.

Waney edge Panels

Design: Waney panels, also known as lap panels, use slightly thinner boards, 5.5mm, compared to featheredge panels. Waney edge slats are machined straight with the other edge being left wavy to give a natural and rustic look.

Waney edge panels have a simple design, using cheaper materials and are a less expensive option to featheredge. Generally, a waney edge fence panel is erected using a 75mm x 75mm wooden post which again, is a cheaper preference to other post options.

The waney edge panel has been around a very long time and is often used for gardens with older fences. It is seen as a less decorative fence panel.

Manufacturing: Waney edge panels comprise of two sets of vertical bars that run from edge to edge, top and bottom end horizontal bars with the waney edge boards sitting between the set of vertical bars, again, providing a privacy screen. The boards are thinner than featheredge boards but a greater width, typically anything between 125mm to 200mm wide.

The overlap varies from around 22mm to 50mm depending on the natural wave cut of the board. Waney panels are braced at intervals using 32 x 16mm battens. The top of the panel is strengthened using a 50 x 19mm bevelled capping rail to prevent rain and moisture penetrating the panel with some manufactures using a bottom timber rail to further enhance the strength.

Waney panels are manufactured in the below sizes -

3ftH x 6ftW

4ftH x 6ftW

5ftH x 6ftW

6ftH x 6ftW

Strength of a waney edge panel: Due to the thinner boards and frame that make up a waney edge panel as well as commonly being paired with thinner posts, they are seen as being less resistant to winds.

Featheredge Panels

Design: Featheredge fence panels, otherwise known as closeboard panels, are manufactured using pressure treated timber that is more heavy duty. Featheredge panels are constructed using vertical boards that partially overlap with each other. The overlap is 25mm to give a 100mm finish coverage. Featheredge panels are commonly finished with a capping rail placed at the top of the panel to provide a tidy and neat appearance.

Featheredge panels are slightly more expensive than Waney edge panels but provide a sleeker and more aesthetically pleasing finish as the boards used are machine cut down both ends.

Featheredge panels offer versatility when pairing with different post types, for example, concrete, DuraPost and wooden.Â

Manufacturing: Featheredge panels, using pressure treated timber, consist of a frame, made up from two end bars, 16mm x 16mm and cross rails, 63mm x 32mm which are fitted horizontally. A capping rail again, finishes off the panel that also allows any moisture or rain to run off the panel. The featheredge boards are then fixed vertically to the rails. Featheredge boards are typically 125mm in width with the thickness of the boards running thin to thick.

Featheredge panels are manufactured in the below sizes -

3ftH x 6ftW

4ftH x 6ftW

5ftH x 6ftW

5ft6”H x 6ftW

6ftH x 6ftW

Strength of a featheredge panel: Featheredge panels, as mentioned, use thicker materials for the boards and overall framework. This creates a sturdy panel that can withstand strong winds and general harsh weather conditions.

Featheredge panels are seen as a more popular option over Waney panels when it comes to strength due to the thicker materials used, albeit being more expensive.